In today’s competitive marketplace, the right packaging can make all the difference. Your product’s label isn’t just an identifier; it’s a silent salesperson, a brand ambassador, and a vital piece of information delivery. For businesses of all sizes, from artisanal producers to large-scale manufacturers, choosing the right printed labels on a roll is a critical decision that impacts efficiency, brand perception, and ultimately, your bottom line. But with an overwhelming array of materials, adhesives, and printing techniques available, how do you navigate the options to select the perfect fit for your specific requirements?

This comprehensive guide will demystify the process, helping you make informed choices that elevate your product and streamline your operations.

Understanding the Advantages of Roll Labels

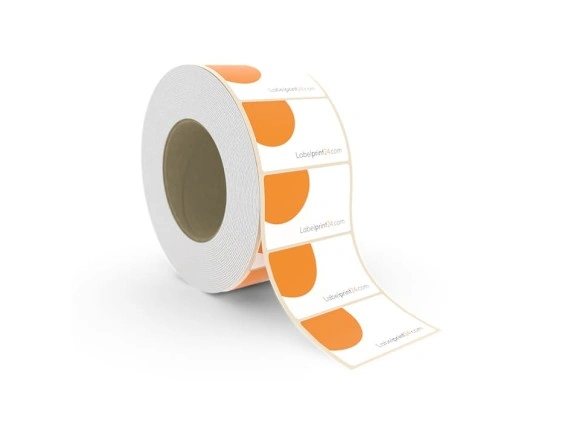

Before diving into the specifics, it’s worth reiterating why printed labels on a roll are the preferred choice for most businesses. Their primary advantage lies in their compatibility with automated labeling equipment. This automation significantly increases production speed, reduces labor costs, and ensures consistent application, which is crucial for high-volume operations. Furthermore, roll labels are often more cost-effective to produce in bulk and are easier to store and manage than individual sheets.

Key Considerations When Selecting Your Printed Labels on a Roll

Choosing the ideal label involves a careful evaluation of several interconnected factors. Let’s break them down:

1. Application Environment and Product Type

This is arguably the most crucial starting point. Where will your label be applied, and what conditions will it endure?

- Temperature Extremes: – Will your product be stored in a freezer, a hot warehouse, or exposed to direct sunlight? Labels for frozen foods, for instance, require specific adhesives and materials that can withstand condensation and low temperatures without peeling or becoming brittle.

- Moisture and Chemicals: – Products like cleaning supplies, beverages, or cosmetics demand labels that are resistant to water, oils, and chemical spills. Vinyl or synthetic materials often outperform paper in such environments.

- Abrasion and Handling: – If your product will be handled frequently, stacked, or shipped long distances, you’ll need durable labels that won’t scuff, tear, or fade easily. Lamination or protective coatings can significantly extend label life.

- Surface Type: – Is your product container smooth, textured, flexible, or rigid? The adhesive needs to be compatible with the surface to ensure a strong, long-lasting bond.

2. Material Matters: Paper vs. Synthetic

The choice of material directly impacts durability, appearance, and cost.

Paper Labels:

- Pros: – Generally, the most economical option, offering a wide range of finishes (matte, semi-gloss, gloss). Excellent for indoor use and non-demanding applications.

- Cons: – Susceptible to moisture damage, tearing, and fading. Not ideal for products exposed to harsh conditions.

- Best for: – Dry goods, internal tracking, general packaging, short-term promotions.

Synthetic Labels (e.g., Polypropylene, Vinyl, Polyester):-

- Pros: – Highly durable, water-resistant, chemical-resistant, tear-resistant, and often UV-stable. Available in clear, white, and metallic finishes.

- Cons: – Higher cost than paper.

- Best for: – Beverages, cosmetics, industrial products, outdoor use, frozen foods, health and beauty items.

- Specialty Materials: – Consider eco-friendly options like recycled paper or biodegradable films for sustainable branding. Textured papers, foils, and clear films can also create unique visual effects.

3. Adhesive Selection: Sticking Power

The adhesive is the glue that holds your brand to your product. It’s not a one-size-fits-all solution.

- Permanent Adhesives: – Designed for a strong, long-lasting bond that is difficult to remove without damaging the label or surface. Ideal for most product labeling.

- Removable Adhesives: – Offer a temporary bond, allowing labels to be peeled off cleanly without leaving residue or damaging the product. Useful for promotional labels, temporary price tags, or items where the label isn’t meant to be permanent.

- Repositionable Adhesives: – A middle ground, allowing for initial repositioning before setting into a more permanent bond.

- Specialty Adhesives: – This category includes freezer-grade, high-tack (for rough surfaces), and water-soluble options. Always discuss your specific needs with your label provider.

4. Printing Techniques and Finishes

The visual appeal of your printed labels on a roll is paramount for attracting customers.

- Digital Printing: – Excellent for short to medium runs, variable data printing (e.g., serial numbers, QR codes), and intricate designs with many colors. Offers quick turnaround times.

- Flexographic Printing: – Cost-effective for medium to large runs, offering vibrant colors and good print quality. Best for simpler designs or consistent branding.

- Offset Printing: – Known for its high-quality, consistent results, often used for very large runs where color accuracy is critical.

Finishes and Embellishments: –

- Lamination: – Adds a protective layer, increasing durability and offering matte, gloss, or soft-touch finishes.

- Varnishes: – Provide a protective coating and can enhance specific areas (spot varnish) or the entire label.

- Foil Stamping: – Adds a metallic, reflective element for a premium look.

- Embossing/Debossing: – Creates raised or recessed tactile effects for a sophisticated feel.

5. Roll Specifications for Automation

If you’re using an automatic labeling machine, the roll’s specifications are critical for seamless operation.

- Core Size: – The diameter of the cardboard tube the labels are wound around (e.g., 3-inch or 6-inch).

- Outer Diameter (OD): The total diameter of the roll, which must fit within your machine’s label holder.

- Wind Direction: – How the labels are oriented on the roll (e.g., top first, bottom first, left edge first). This is crucial for correct application.

- Gap Between Labels: – The space between individual labels on the roll, which the machine uses for sensing.

Actionable Tips for Selection

Test, Test, Test: – Always request samples of your chosen material and adhesive. Apply them to your actual product and subject them to the expected environmental conditions. A small investment in testing can prevent costly errors down the line.

Consult with Experts: – Don’t hesitate to leverage the knowledge of your label printing partner. They can offer invaluable insights into materials, adhesives, and printing techniques best suited for your specific application.

Consider Future Needs: – Are you planning to expand your product line or introduce new packaging? Choose a label solution that can scale with your business.

Prioritize Clarity: – Ensure all essential information (ingredients, warnings, barcodes) is legible and complies with industry regulations.

Conclusion

Choosing the right printed labels on a roll is a strategic business decision that extends beyond aesthetics. By carefully considering your product’s environment, material needs, adhesive requirements, printing techniques, and automation specifications, you can select labels that not only look fantastic but also perform flawlessly. A well-chosen label protects your product, enhances your brand, and ultimately contributes to your business’s success in a competitive market. Invest the time now to make an informed choice, and watch your products stand out on the shelves.